PP WPC wall panels, thinga siam fiber leh recycled plastic inzawmkhawm hmanga siam chu a sakna leh a pawn lam design sector-ah a lar chho zel a ni. Heng panel-te hian hnam lam thilte ai chuan sustainable leh eco-friendly alternative a pe a, thinga natural aesthetic appeal leh plastic enkawlna hniam leh enkawlna hniam tak takte chu a inzawm khawm a ni. PP WPC Wall panels siamchhuahnaah hian thil pawimawh engemaw zat a awm a, chu chu final product-in quality leh performance standard a tlin theih nan a pawimawh hle. He thuziak hian PP WPC wall panel siam dan inthup dan a zirchiang dawn a, stage tin hnuaia technology awm dan leh heng thil thar siam chhuah te hlawkna a tarlang dawn a ni.

Double-sided PP WPC Wall Panels atana raw material buatsaih dan

PP WPC (wood plastic composite) wall panel siam chhuah hi raw materials uluk taka thlan leh buatsaih atanga tan a ni. He stage hi a pawimawh hle a, final product quality leh performance atana lungphum a phum avangin. PP WPC-a thil pawimawh ber chu thinga siam fiber leh recycled plastic te an ni a, chu chu an duh ang mizia an neih theih nan ratio bik hmanga inzawmkhawm a ni.

Thing fibers: Sourcing leh processing .

Wood fibers, composite-a natural component chu sawmill residue, thing chips, emaw recycled wood products atanga lak chhuah a ni tlangpui. Heng fibers te hi plastic material nena an inmilna leh an inmil theih nan thlan an ni. Thing fibers processing-ah hian drying leh milling a awm a, chu chuan a size leh moisture content inmil a siam thei a, hei hi optimal mixing leh extrusion atan a pawimawh hle. Thing fiber siam fel tak chuan plastic matrix nen inzawmna tha tak a siam a, chu chuan composite-a mechanical property a tichak a ni.

Plastics: chi hrang hrang leh an chanvo te chu composite ah hian .

Recycled plastics (polypropylene), chu composite-a synthetic component a ni. Heng plastic te hi an chhe thei lo, chemical resistance, leh environment sustainability atan thlan an ni. Plastic thlan hian composite-a flexibility, impact resistance, leh weatherability te a nghawng a ni. Plastics te hi tihfai hmanga process a ni a, shredding to remove contaminants, consistent mixing leh extrusion atana pawimawh tak a ni.

Mixing leh compounding: uniformity tihhlawhtlinna .

A dawt leh tur chu thinga siam fiber leh recycled plastic siamte chu ratio dik takah a pawlh a, chu chu a tawp bera thil siam chhuah duh dan azirin a ni. Hetiang hian granulator hmanga tih a ni tlangpui a, chu chuan a hmanrua te chu uluk taka inzawmkhawm leh compounding a ti thei a ni.

Mixing zawhah compounded material chu a lum a, pelletized a ni a, chu chuan uniform pellets chu a siam chhuah lehna tur stage dang atan a inpeih ta a ni. Heng pellets te hi extrusion process atana raw material atan an thawk a, chutah chuan final PP WPC wall panels ah an inthlak ang. Raw materials uluk taka buatsaih hi tunlai construction leh design mamawh phuhruk thei PP WPC wall panel quality sang tak siam chhuahna atan a pawimawh hle.

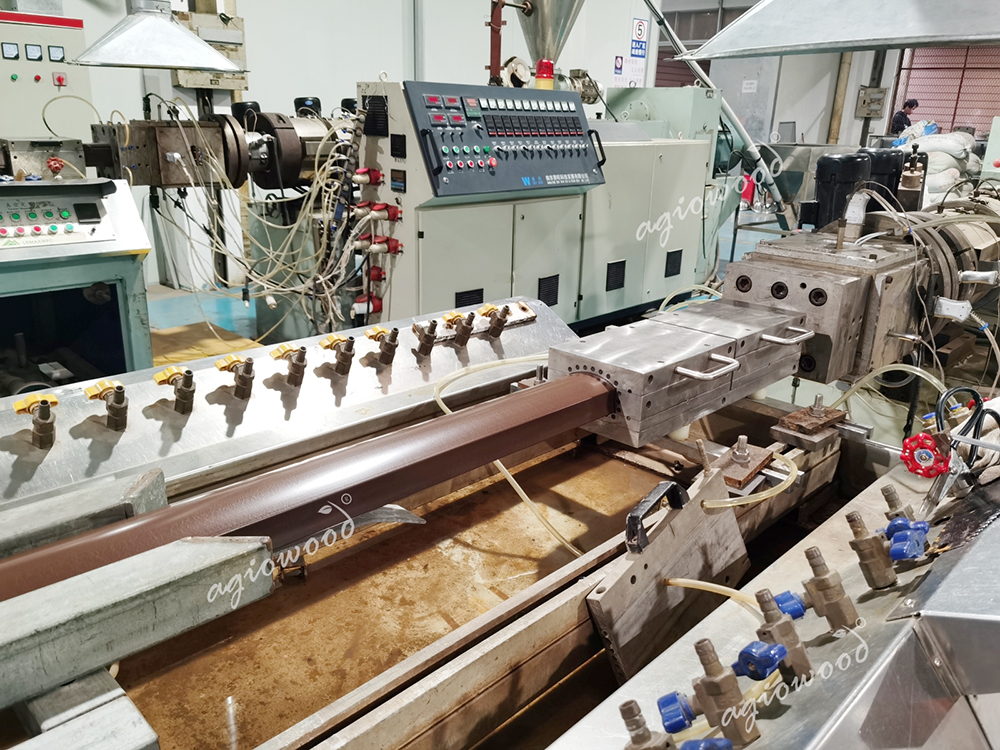

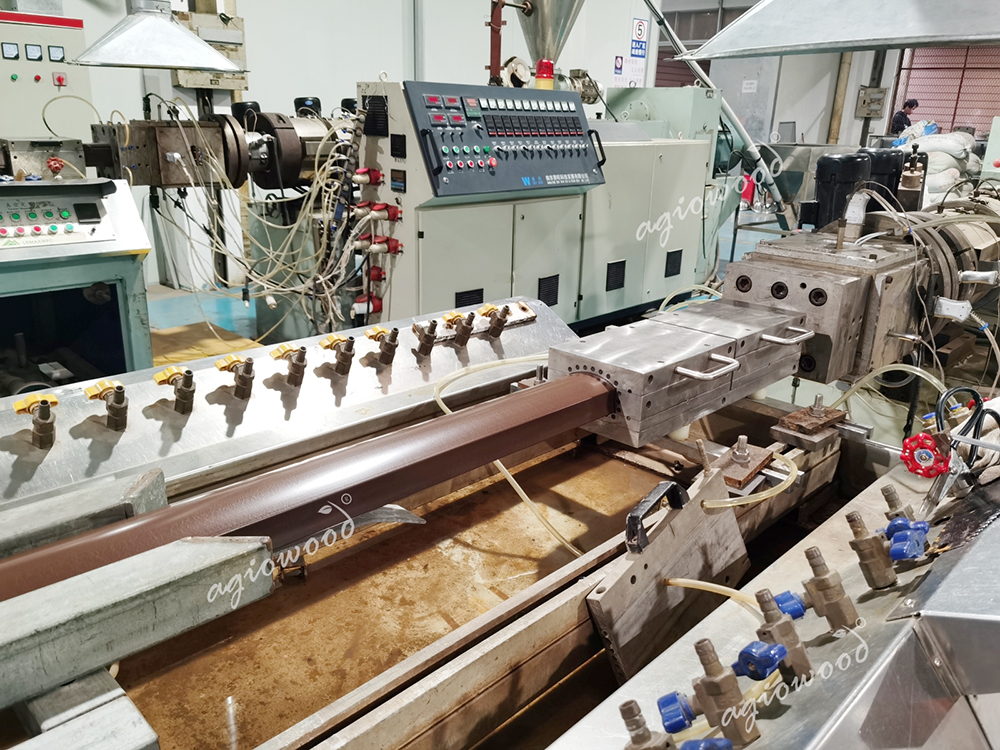

Extrusion: PP WPC Wall Panels siam dan .

Extrusion hi PP WPC (wood plastic composite) wall panel siamna atana thil pawimawh tak a ni. Hetiang hian thinga siam fiber leh recycled plastic te chu uniform mixture chu composite material continuous sheet ah a chantir a, processing further processing atan a inpeih reng a ni. Panel thickness, texture leh overall quality a hriat chian avangin extrusion process hi a pawimawh hle.

Extruder Setup: A chi leh a configuration te .

Extruder hi thil siam chhuahna thinlung a ni a, chutah chuan a buatsaih sa chu a chawm a, a hmin a, a lem a siam a ni. Extruder chi hrang hrang hman theih a ni a, extruder thlan dan tur chu production line-a thil mamawh bik, output duh, panel dimension, leh material property-ah a innghat a ni.

Chaw pek leh melting: homogeneous mixture tihhlawhtlinna .

Extruder chu pellets siam dik tak hmanga chaw pek hi homogeneous mixture a nih theih nan a pawimawh hle. Extruder’s feed zone hi pellets te chu zawi zawiin melting zone chhunga hruai lut turin an siam a, chutah chuan controlled heat leh shear an tawk a ni. Hetiang hian plastic components te chu a melt a, thing fibre te chu a ti nem a, mixing atan a buatsaih a ni. He stage chhunga temperature leh pressure dik tak vawn reng hi thil siamte tihchhiat loh nan leh melt flow mumal tak neih theih nan a pawimawh hle.

Molding: Panel te siam dan tur .

Vawikhat chu a hmin tha tawk leh homogeneous a nih chuan die hmangin force a ni a, chu chuan duh ang panel thickness leh width ah a siam a ni. Panel profile leh surface texture a sawifiah avangin die design hi a pawimawh hle. PP WPC wall panels tan chuan die hi a sir lehlama surface mumal tak, inmil tak siam tura siam a ni a, hei hi aesthetic appeal leh functional performance atan a pawimawh hle.

Cooling: Panel solidifying .

Die hnuai lama cooling system hian panels solidify-na kawngah hmun pawimawh tak a chang a ni. Extrusion hnuah panel te chu an dimension leh quality standards tarlan te an tlin theih nan an ti lum a, warping emaw distortion emaw an veng thei bawk.

Cutting leh finishing: Final product atana inbuatsaihna .

Extrusion process zawhah PP WPC (wood plastic composite) wall panels te chuan final product assembly leh installation atana buatsaih turin cutting leh finishing an nei thin. He stage hi panel-te’n application hrang hrang atana an mamawh ang chiah leh an tawp dan tur dik tak an tlin theih nan a pawimawh hle. Cutting leh finishing process-ah hian step pawimawh engemaw zat a awm a, chu chu panel-te hnathawh dan leh aesthetic appeal tihsan nan ruahman a ni.

Cutting: Panel dimensions atan precision a awm.

Cutting leh finishing stage-a step hmasa ber chu extruded panels te chu duh ang dimension-a cut a ni. He process hi a pawimawh hle a, panels te final size leh shape a tihfel avangin. Precision cutting hian panel-te chu an hman tumnaah a inmil tawk tih a tichiang a, chu chu interior bang emaw, pawn lam cladding emaw, architectural use dang emaw atan pawh ni se. Advanced cutting technology, electronic table-saw ang chi te hi precision sang tak leh edge thianghlim tak neih theih nan an hmang fo thin.

Finishing: Aesthetics leh Performance tihsan .

finishing chu final touch a ni a, chu chuan aesthetic leh functional qualities te chu a tichak a ni. PP WPC Wall Panels . Hetiang kalphung hian panel-te chu sanding emaw, texturing emaw a ni thei a, chu chuan a bik takin a en thei ang.

Quality Control: Standards enkawl dan tur .

Quality control hi cutting leh finishing stage-a thil pawimawh tak a ni. Panel-te chu an hnathawh emaw, an hmel emaw tichhe thei thil dik lo emaw, inmil lohna emaw a awm leh awm loh enfiah a huam a ni. Quality control measures-ah hian hmuh theiha enfiahna, dimensional check, leh performance test te a tel thei. Panel eng pawh, standard mamawh phuhruk lo chu siam thar emaw, hnawl emaw a ni a, chu chuan thil siam quality sang ber berte chauh chu market-ah a thleng thei tih a tichiang a ni.

Tawpna

PP WPC (wood plastic composite) wall panel siam hi thil buaithlak tak a ni a, uluk taka thlan leh raw material siam, extrusion dik tak, leh uluk taka cut leh finishing te a ni. A tawp bera thil siam chhuah chu quality, durability, leh aesthetic appeal standard sang ber a tlin theih nan a pawimawh hle. Heng thil pawimawh tak takte hi hriatthiamna leh thiam taka hman a nih chuan, thil siamtute chuan PP WPC wall panel an siam thei a, chu chuan tunlai construction leh design-a thil phut a phuhruk mai bakah, building kalphung nghet tak a siam thei bawk.